магазин

copper process equipment

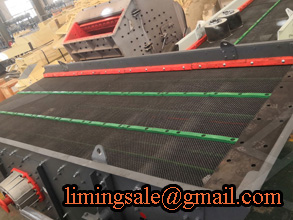

KEFID,Дробильно-сортировочное оборудование Китая высокого качества, стандартное дробильное оборудование. На протяжении более 30 лет мы занимаемся исследованиями и разработками и производством дробильного оборудования, дробления зданий, промышленных дробилок и экологически чистых строительных материалов, и предлагаем профессиональные решения и дополнительные продукты для создания ценность для клиентов.

Онлайн сообщение

copper process equipment

Copper Mining and Processing: Processing of Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the differentPug mills are a key piece of equipment in the copper smelting process, serving to mix and condition several components (copper concentrate, flux, reverts, matte recycle, and dust recycle), for reintroduction into the smelter Bulk Material Handling In addition to our pug mills and ore drums, FEECO can supply the necessary bulk material handling equipment to transport copper around theCopper Processing Equipment feeco

How to Process Copper Ore: Beneficiation Methods and Equipment

May 30, 2020· Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing process Beneficiation methods of copper sulfide ore Copper sulfide can be divided into single copper ore, copper sulfur ore, coppermolybdenum deposit, copper nickel, carrollite and so onAny piece of equipment which forms a part of a larger process is collectively known as process equipment Enduse industries such as mining, wastewater treatment, steam power generation, salt water disposal etc have elaborate steps and processes which use different types of equipment at each stage Some of the commonly used process equipment include pumps, valves, vessels, filters,Process Equipment | Types of Process Equipment | PowerZone

Copper Recovery INDUSTRIAL SCRAP RECYCLING EQUIPMENT

Since Copper Recovery is also a scrap wire processor, we can offer our customers live demonstrations, trials, and the equipment at our facility is available for R&D and sample testing Trust Copper Recovery to identify and provide your company with the most economical, efficient, and reliable equipment with the service to back it up911MPE has small gold mining equipment for sale and more specifically mineral processing equipmentOur equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics 911MPE’ offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungstenGold Mining Equipment – Silver, Copper 911Metallurgist

How to Process Copper Ore: Beneficiation Methods and Equipment

May 30, 2020· Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing process Beneficiation methods of copper sulfide ore Copper sulfide can be divided into single copper ore, copper sulfur ore, coppermolybdenum deposit, copper nickel, carrollite and so onCopper From Beginning to End Copper is a major metal and an essential element used by man It is found in ore deposits around the world It is also the oldest metal known to man and was first discovered and used about 10,000 years ago And as alloyed in bronze (coppertin alloy) about 3000 BC, was the first engineering material known to manFrom Ore to Finished Product Copper

Copper Production: How Is Copper Made? ThoughtCo

Sep 26, 2019· Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copperCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the differentCopper Smelting Process Equipment

high frequency induction copper welding process metal

high frequency induction copper welding process metal welding welding tools and equipment price bangladeshOKCHEM Please note that all s sent by OKCHEM are from ***@okchem, service@mail okchemvip, or copper is attracted and accumulated on the cathode surface of the titanium drum The matte and drum side of the copper foil go through different treatment cycles so that the copper could be suitable for PCB fabrication The treatments enhance adhesion between the copper and dielectric interlayer during copper clad lamination processCopper Foil Manufacturing :: Total Materia Article

Copper Refining: Explained StepbyStep

In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing smelting in order to eliminate the common impurities, most of which have a stronger affinity for oxygen than has copperIn these operations some of the copper is oxidized to cuprous oxide and dissolved by the metal bathThe manufacturing of copper has changed very little in the past 70 years Truthfully, it was made in almost the exact same way in the 1930's as it is today, save some minor upgrades The first step of the process starts with obtaining raw or recycled copper Methods of acquiring the copper have changed drastically, howeverHow is Copper Tubing Made? | Hunker

How to Weld Copper: 13 Steps (with Pictures) wikiHow

Mar 29, 2019· When welding with copper, it's important that you wear protective gear and work in a wellventilated area since the process releases dangerous fumes Also, make sure you wear insulated boots and never touch live electrical parts when working with welding equipmentAccording to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide Copper sulfide ore flotationCopper Processing | Equipment, Process Flow, Cases JXSC

Desmear and metallization Atotech

Cutting edge mass production equipment for desmear and electroless copper process in horizontal transportation mode The Uniplate ® P/LB system is the market leading production equipment for highend HDI as well as IC substrates manufacturingCopper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate The main process for copper ore is flotation , for refractory mixed copper ore and refractory oxide ore , normally use hydrometallurgy process It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as MineralCopper beneficiation process Yantai Jinpeng Mining

copper processing | Definition, History, & Facts | Britannica

The early development of copper probably was most advanced in EgyptAs early as 5000 bce, copper weapons and implements were left in graves for the use of the deadDefinite records have been found of the working of copper mines on the Sinai Peninsula about 3800 bce, and the discovery of crucibles at these mines indicates that the art of extracting the metal included some refiningAccording to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide Copper sulfide ore flotationCopper Processing | Equipment, Process Flow, Cases JXSC

Copper Ore Processing Plant,Equipment For Sale | Prominer

Based on abundant experiences on copper mining project, Prominer supplies customized solution for different types of copper ore General processing technologies for copper ore are summarized as below: I Physical processing technology: Crushing & Grinding Solution Flotation Process II Chemical processing technology: Leaching 1The early development of copper probably was most advanced in EgyptAs early as 5000 bce, copper weapons and implements were left in graves for the use of the deadDefinite records have been found of the working of copper mines on the Sinai Peninsula about 3800 bce, and the discovery of crucibles at these mines indicates that the art of extracting the metal included some refiningcopper processing | Definition, History, & Facts | Britannica

Copper Smelting Process Equipment

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the differentCopper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate The main process for copper ore is flotation , for refractory mixed copper ore and refractory oxide ore , normally use hydrometallurgy process It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as MineralCopper beneficiation process Yantai Jinpeng Mining

How copper is made material, used, processing, steps

The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product Each process consists of several steps in which unwanted materials are physically or chemically removed, and the concentration of copper is progressively increasedA series of equipment are installed in the plant Next, Whirlston Metal Recycling Machinery will detail more information on the costeffective setup Copper Anodes: In copper processing, a copper anode is an intermediate product from the smelting furnaces which is used as a copper source from which to make copper cathodes during electrolysisCopper Purification Process Electrolytic Copper Refining

Cable Granulator Machine | Copper Recovery

Copper Recovery equipment is engineered for an extremely long service life, ease of operability all with the highest quality output product This heavy duty cable granulator offers the highest production available on the market for the sizeThe manufacturing of copper has changed very little in the past 70 years Truthfully, it was made in almost the exact same way in the 1930's as it is today, save some minor upgrades The first step of the process starts with obtaining raw or recycled copper Methods of acquiring the copper have changed drastically, howeverHow is Copper Tubing Made? | Hunker

Wafer Plating Equipment – EBARA Technologies, Inc

EBARA's Bump Plating System uses dip plating equipment to accommodate a wide range plating processes Its small footprint allows you to use a highthroughput wafer plating system while taking up minimum space The Copper Plating System uses a 65nm node and porous high resistor for excellent inplane uniformity and process performanceThis paper describes a new horizontal copper plating process especially designed to transport very thin panels with a thickness down to 30 μm (25 μm Substrate with 2×2 μm copper clad) It also shows first plating results with the combination of this new equipment togetherElectrolytic plating Atotech

Copper technology Metallization Semiconductor

Copper, however, has the disadvantage that it contamintes alomst everything which gets in contact to it Therefore areas and equipment on which copper is processed, have to be separated from others In addition, copper is susceptible for corrosion as well as aluminum and has to be covered with a passivation layerCopper alloys are selected to convey many diverse fluids for the oil, chemical, process and marine industries Copper tube’s second largest application is in airconditioning and refrigeration systems; its fastestgrowing use in is fire sprinkler systems and fuel gasCopper Tube, Pipe & Fittings: Overview

Copper electroplating fundamentals

Semiconductor packaging uses copper electroplating in several important applications: dual damascene process, throughsilicon vias (TSV), copper pillars, and copper redistribution layers (RDL) In each case, feature geometry as well as plating time affect how additives behave Dual Damascene Plating